The Imbalance of Cost Cuttings

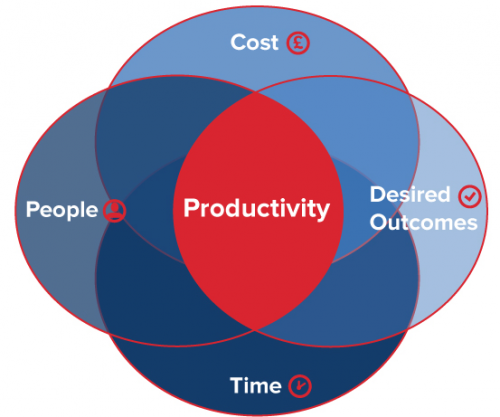

If business was a ven diagram it would look something like this:

Whatever market you’re in, there’s always a balance to be struck between these business basics as without that harmony costs can run amok, productivity can dwindle, time gets wasted and good employees drift away.

All these things lead to a terrible customer experience and, ultimately, a failed business.

The ATM world is no exception.

There is a temptation, when maintaining your network to keep a hawkish eye on costs. Cheaper parts means savings, savings improves the bottom line.

However cheap is usually another word for inferior. Your suppliers have to maintain their margins too and if critical modules are cheap they are cheap for a reason.

Cheaper modules don’t just result in consistent ATM failures and increased downtime, but a frustrated and disenfranchised customer base.

Moreover, persistent failures have a significant impact on revenue. Increasing the frequency of reactive engineer visits which also quickly erodes any profit margin achieved.

The hidden costs of buying cheaper doesn’t just include the cost of the part. It may impact profitability through lost transactions but in other ways too; time and money sourcing replacement parts, processing orders, shipping arrangements, arranging another engineer visit.

All time and effort that could be invested in winning new business, improving service to existing customers and improving employee efficiency.

Independent ATM deployers may well be hit doubly hard as they don’t all have the luxury of an established brand to fall back on in the same way high street banks do.

It’s for this reason that IADs have to establish a reputation as convenient and utterly infallible. Your network has to be the first choice, not a last resort.

To go back to our diagram, cost cutting can save money but increases the chances of component failure which impacts on time and desired outcomes, stalling productivity, or in this case: up time.

The answer is clear: invest in parts and machines that will help you to hit your uptime targets.

Buying quality parts that have been rigorously tested to guarantee longer lifetimes will reduce repeat maintenance visits, ATM failures and repeat ordering of parts.

This actually cuts costs, reduces downtimes and improves the customer experience.

However, whilst investing in reliable parts; manufactured to the exact specifications for the machine in question is vital, it goes deeper than that.

Buying better parts prolongs the uptime of a machine but no matter how well made they are, everything wears out eventually.

Preventative maintenance not only makes sure the best, tried and tested, components go into your ATM machines but that they go in before the machine fails.

The swapped out parts can then be refurbished back up to factory standard and eventually put back into circulation.

This has a naturally harmonising effect on an ATM business. Costs are consistent and easily budgeted for as preventative maintenance is an agreed price. Maintenance is proactive rather than reactive so time is used more efficiently and because machines are working, transactions increase in line with improved uptime.

If you would like to know more about our parts service, call TestLink today.